NIDC saves $133,000 in drilling costs through manufacturing of 70 high-demand parts

TEHRAN - The Head of the Engineering and Construction Technology Department of the National Iranian Drilling Company (NIDC), referring to the manufacturing of 70 high-consumption parts in the drilling industry during the first half of this Iranian calendar year (March 21-September 22), stated: "The manufacturing of these parts, in cooperation with knowledge-based companies and domestic manufacturers, has resulted in savings of 133 billion rials (about $133,000) in company costs based on calculations made."

Masoud Seyed Mahmoudi stated: "The National Iranian Drilling Company is one of the pioneering companies in the oil industry regarding its focus on domestic manufacturing and has over two decades of history of interaction and cooperation with domestic manufacturers and industrialists in the field of technical and engineering knowledge."

He pointed to the manufacturing of 5,019 parts and 633 pieces of equipment, with a total and breakdown of 23,576 parts, and added: "The number of parts and equipment manufactured in recent years shows an eight-percent growth compared to the past."

The official further explained that, besides savings and after-sales service, an important advantage of focusing on domestic manufacturing is the cessation of purchasing these parts and equipment from abroad, stating: "Domestically produced parts are being localized with priority given to high-consumption and essential parts."

Regarding the most important achievements of the Research, Technology, and Construction Engineering Management of the National Iranian Drilling Company in the field of manufacturing parts and equipment, he stated: "In the drilling operations sector, we can mention the manufacturing of air, oil, and fuel filters for Caterpillar engines; the main shaft of various top drives; fluid screens; various Checkmate and Demco valves; RING JOINT GASKET; various PLUG VALVES; liner and module for various mud pumps; engine radiators; 5/8, 13, and 20-inch packing elements; drilling rig pins; lifting sleeves; brake rim draw works; mud pump connecting rod; and some top drive parts."

Seyed Mahmoudi said: "In the technical and specialized drilling services sector, various parts and equipment, including logging sensors, butterfly valves, high-pressure cementing pipes, the underbalanced drilling rotary BOP stack, OVER SHOT tools, DESANDER UNIT, MOT, SURGE DRUM, MOT, and DISILTER UNIT, MOT have been localized."

The Head of the Engineering and Construction Technology Department of the National Iranian Drilling Company added: "The Research, Technology, and Construction Engineering Management of the company has also placed on its agenda the first-time production of strategic and key drilling industry equipment, with the aim of supporting domestic production and maximizing the use of capacities under Article 10 of the Law on Knowledge-Based Production Leap, and by utilizing the potential of knowledge-based companies active in the country's oil industry."

He stated: "In the drilling operations activity sector, the design and manufacturing of main diesel generators for drilling rigs, drilling mud pumps, drilling rig draw works, rotary tables, blowout control equipment, drilling jars, drilling fluid service centrifuges, and in the technical services activity sector, the design and manufacturing of cementing pump trucks, mobile wireline units, mobile wireline inspection units, and cementing service densitometers are underway."

In mid-September, the NIDC managing director said that the company had built its second mobile oil treatment (MOT) unit using in-house expertise and equipment.

Mehran Makvandi noted the company’s engineers had focused on innovation, integrated technical services and software solutions to improve drilling operations. He said the new unit offers faster deployment and higher reliability than the first domestically produced system.

While earlier models required two or three trailers, the latest unit is mounted on a single trailer, allowing for quicker transport, installation and operation, he added.

The MOT unit is designed to process crude oil directly at the wellhead by removing water, salt, sediments and associated gases before sending the treated oil to pipelines or refineries. It was recently tested at wells 37 and 38 in the Lali oilfield operated by the National Iranian South Oil Company, with results approved by the client. The system is now in use for well repair operations near Ahvaz.

Makvandi said the technology boosts production, prevents wastage and helps meet the Oil Ministry’s policy of banning crude burning in open pits. By reducing on-site flaring, the MOT also mitigates air and water pollution.

The new unit can process up to 5,000 barrels per day at 800 psi pumping pressure, making it a valuable tool for environmental protection and cost efficiency, he said.

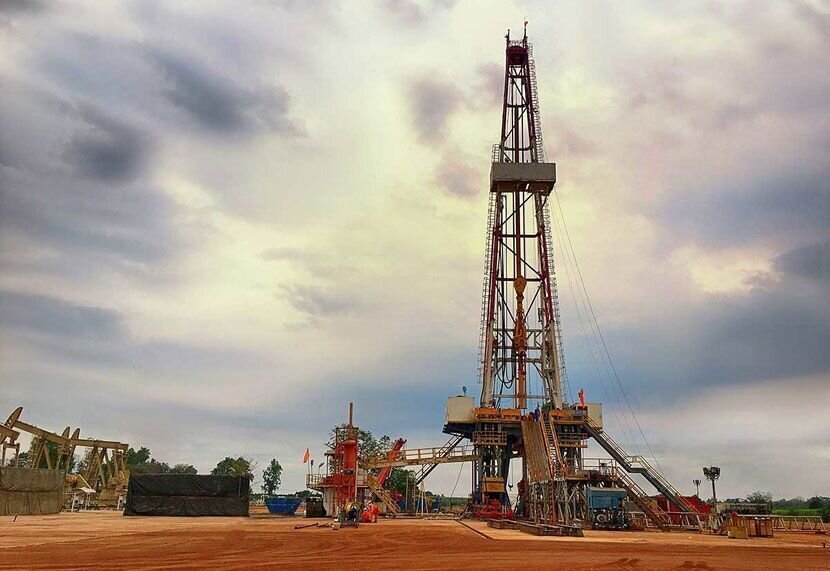

National Iranian Drilling Company, a subsidiary of the National Iranian Oil Company (NIOC), is a key player in Iran's oil and gas industry, responsible for drilling operations.

The company that conducts exploration, development, and drilling of oil and gas wells, as well as repair and maintenance services, and has been actively involved in both onshore and offshore drilling projects, is now ready to play a more prominent role in the region.

The deputy managing director of the company has announced the implementation of a comprehensive program to modernize the drilling fleet, widely localize equipment, manufacture a national drilling engine, and set a goal of repairing and completing 150 wells by the end of this year, emphasizing: "Based on decades of experience, this company is ready to play a more prominent role at the regional level."

Regarding the most important challenges of the NIDC due to sanctions, Masoud Afshar has stated: "Domestic production of many equipment has reduced dependence on foreign countries, but in the engine sector, we had challenges that are being resolved with the new contract. The production of SCR, cables, and tanks are other successful examples of self-sufficiency."

“Our experts are currently involved in international projects, and the successful drilling experience in Turkmenistan will be a basis for expanding activities in other neighboring countries”, the official has underlined.

Afshar has emphasized that with the development of technology, self-sufficiency in equipment, and the benefit of efficient human resources, the National Drilling Company is firmly on the path of sustainable development and is ready to play a more effective role in the regional arena.

Meanwhile, the managing director of the company has explained the outlook for the development of the drilling industry in the country, and said: "The most important global indicator in the field of drilling is the reduction of unproductive times; so, we have reduced this indicator from 21 percent to about 9.6 percent and set a goal to reach below three percent."

Mehran Makvandi said that in the five-year outlook, the modernization of the onshore and offshore drilling fleet, the development of offshore drilling in the Persian Gulf oil fields, and the upgrading of technical service equipment and their integration are priorities.

Regarding digital developments in the company, he stated: "Digitalization of drilling processes, from design and monitoring to operation analysis and well data management, is one of the main axes of the company's future vision; this approach will lead to reduced errors, faster decision-making, economic savings, and greater safety."

In addition to upgrading equipment, strengthening cooperation with scientific centers and knowledge-based companies, developing human resources, and increasing competitiveness in the international market are also among the company's strategic priorities in the 5-year outlook, the official added.

The NIDC managing director has also referred to the company's move towards domestic production of the equipment, and said: "One of the strategic priorities of the National Iranian Drilling Company is to increase the share of domestic manufacturing.”

“In this regard, cooperation has been developed with companies such as Fajr Shiraz Complex, which has experience in manufacturing key components of drilling rigs. The project to build the third drilling rig in the country with a savings of seven million dollars is an example of these measures", Makvandi added.

According to him, prioritization is based on the operational needs of the fields, the type of projects, and domestic capacity, although the lack of some technical infrastructure, the need for technology transfer, and the timely supply of quality parts are some of the challenges on the localization path. However, the company is determined to strengthen domestic manufacturing and reduce dependence.

Makvandi further referred to the NIDC’s contracts with knowledge-based companies and added: "Nine one-megawatt generator motors and four drilling fluid purification centrifuges, which were previously imported, will be manufactured inside the country, and the first samples will be delivered by the end of the [current Iranian] year (March 20, 2026)."

He also noted: “A specific roadmap has been developed for utilizing these technologies, which includes continuous cooperation with science and technology parks, universities, knowledge-based companies, and the formation of specialized working groups to evaluate and implement technologies in field operations.”

The NIDC managing director has also stated that purchasing 15 new drilling rigs for the oil and gas industry is on the agenda.

Makvandi said that a plan to purchase 15 onshore drilling rigs with different capacities and a value of over $800 million has been prepared, which is being implemented with the support of the Ministry of Oil and the National Iranian Oil Company (NIOC).

Pointing out that last year, the company was able to drill, repair, and complete 100 oil and gas wells using 62 active drilling rigs and the return of two more rigs to operational lines, he added: "Of this number, 24 were development and explanatory wells and 76 were dedicated to repair and completion operations."

He attributed this success to careful planning, interdepartmental coordination, increased operational efficiency, and strengthened integrated technical services, and noted: “This performance is a significant leap compared to previous years, given the economic and sanctions conditions.”

Makvandi stated that the reactivation of idle rigs played an effective role in this success, adding: "Increasing productivity, reducing unproductive times, and relying on domestic capacity are the main pillars of this achievement."

The managing director of the NIDC further emphasized: "These rigs are designed for descriptive and exploratory purposes and will be equipped with the latest technologies. Specialized technical service equipment including high-pressure pumps, and well testing are also on the purchase list."

He continued: "The convergence of this equipment with the current fleet and the integrated planning management of the National Iranian Oil Company is underway in the form of a joint supervisory working group and in coordination with the Ministry of Oil."

Makvandi has said the company’s primary mission is to provide drilling services and specialized operations for oil and gas producers, describing drilling as “the front line of production” and a vital step in preserving and boosting output.

Of the 100 wells completed in the past year, 24 were development wells and 76 were workovers. A total of 74 wells—14 development and 60 workover wells—were handed over to the National Iranian South Oil Company (NISOC), he said.

The official added that 11 wells were drilled in fields managed by the Central Oil Fields Company, three by the Iranian Offshore Oil Company, seven under development projects run by the Petroleum Engineering and Development Company, and five were completed on a project basis.

He emphasized the strategic role of the National Drilling Company as one of the upstream arms of the National Iranian Oil Company, contributing to hydrocarbon supply and helping reduce Iran’s energy imbalance. A portion of the company's resources is currently allocated to drilling gas wells, he said.

The total drilling footage reached 113,520 meters in 1403, up by 28,863 meters from the previous year, which Makvandi attributed to a more than fivefold increase in development well drilling. During the same period, the company carried out 4,538 technical service operations and 1,473 special service operations across more than 20 specialized service categories—marking a significant rise compared to the previous year.

Makvandi also noted that 17 drilling rigs were relocated across operational zones. Of the company’s 74 land and offshore rigs, 64 are currently active in 10 provinces, engaged in development, appraisal, exploration, and repair-completion projects.

Looking ahead, Makvandi said the company aims to accelerate drilling operations and fulfill the strategic plans issued by NIOC in the Iranian year 1404 (starting March 21, 2025). This includes the continuation of equipment modernization efforts that began in 1403.

“With the strengthening of our fleet, rig upgrades, and the adoption of new technologies, we expect to see a major leap in productivity, reduced drilling downtime, improved efficiency, and increased revenue,” he said.

MA

Leave a Comment