Iran on the way to reduce dependence in power plant equipment industry

TEHRAN- Strengthening domestic production to achieve self-reliance is Iran’s major strategy to tackle the sanctions.

Among different sectors, the role of the energy sector is of vital importance in this due.

In the current Iranian calendar year (began on March 20), which is named the year of surge in production, the Energy Ministry has outlined its main programs to materialize this motto.

The ministry’s programs in this regard have been defined in 13 major axes.

Energy Minister Reza Ardakanian has said that his ministry, as an executive body, has a crucial role to play in providing water and electricity infrastructure to achieve the goals of the surge in production, adding that production sectors across the country should be sure about adequate water and electricity supply.

To this end, the ministry has set some programs for the domestic production of this sector’s imported equipment.

Power plant equipment is one of the major items that its domestic production is seriously pursued by the ministry.

The ministry has already achieved knowledge for the domestic manufacturing of several pieces of equipment in this sector.

Oxygen analyzer, which is used to measure the concentration of oxygen (O2) in flue gas, is an example.

In mid-November, an official with Iran's Thermal Power Plants Holding Company (TPPH) announced that for the first time in the country, the oxygen analyzer required by power plants, which was previously imported and a lot of money was paid to buy a foreign sample of this device, was designed and manufactured by domestic experts.

Esmaeil Namazi, the director-general of the technical affairs department of the holding, pointed out: “Domestic manufacturing of this equipment was a step toward surge in production in this year, and with the successful implementation of this project while preventing the outflow of foreign currency to buy oxygen analyzers needed by the country's industries, another important step was taken to reduce the dependence of domestic industries on foreign sources”.

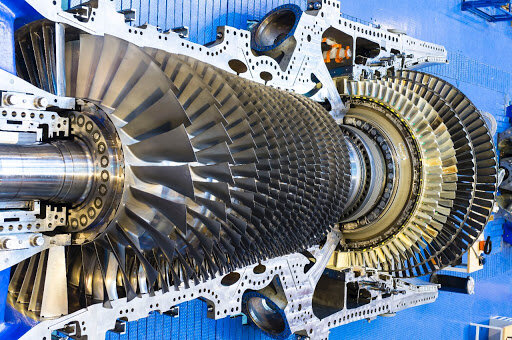

F-class gas turbine is the other item in this regard.

Iran used to import this piece of equipment from foreign sources such as Siemens of Germany.

But now the country has achieved the technology to manufacture this kind of turbine, which is used in the power plants with high efficiency.

Announcing that Iranian experts have achieved the technical knowhow to design and manufacture F-class gas turbine used in the combined-cycle power plants, Alireza Nasrollhai, the operator of the combined-cycle and thermal power plants projects, has recently said, “In the past, we lack the engineering capability to design the gas turbines; but now we have achieved the technical knowledge and this kind of turbine is designed and manufactured completely by Mapna Group.”

E-class gas turbine previously manufactured domestically had an efficiency of 34 percent, while the F-class turbine has an efficiency of nearly 40 percent, which will play an outstanding part in boosting the efficiency of the power plants.

Enjoying such technology, Iran is now among the countries capable of building power plants with high efficiency.

Leave a Comment